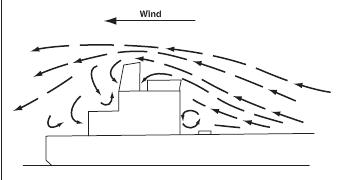

Fig:Air flow over an accommodation block

During cargo operations flammable or toxic gases can eddy and

sometimes these can cause pockets of gas to be present in the most

unexpected places. Where they form depends on wind speed and

direction; a wind blowing from forward may cause gases to

accumulate aft of the superstructure.

Responsibility

(1) It is the responsibility of the master to ensure that the officers and crew are properly and correctly informed of their duties, and understand how to fulfill them.

(2) The master or an officer appointed by him is responsible for the safety of the ship and all cargo operations. The responsible officer should be present at all times and be satisfied that all equipments under his care is in good working condition.

(3) The master should ensure that there is proper liaison between the responsible officer on the ship and his counterpart at the shore installation (See Ship / Shore Safety Checklist ).

(4) Details of emergency contact name, positions, telephone numbers etc. should be distributed before cargo operations begin. Any special safety requirements of the shore installation should be brought to the attention of those concerned.

precautions during cargo operations

- be vigilant at all times especially during cargo operations and

maintenance of cargo equipment

- IF IN CONTACT WITH TOXIC VAPOUR OR LIQUID

, REMOVE CONTAMINATED CLOTHING IMMEDIATELY

, WASH WITH LARGE QUANTITIES OF WATER

- INFORM AN OFFICER

-

do not eat, drink or smoke unless you have thoroughly washed.

-

- always prevent hands coming into contact with your mouth

- be sure you know where decontamination showers are located.

- wear a protective suit and breathing apparatus when necessary

In port watchkeeping procedures

The following is a brief summary of requirements:

A Cargo Plan approved by the Master should be displayed in the CCR, the Cargo Engineer and each

watchkeeping officer should study and sign the plan. The Chief Engineer should also sign the

bunker section as appropriate.

The Chief Officer, and/or Cargo Engineer, will be on duty at critical points during cargo operations.

Throughout the entire cargo handling period, either the Chief Officer, or the Cargo Engineer, has to

be immediately available.

The Cargo Engineer assumes operational responsibility for the cargo during certain in-port periods.

The handover between the Chief Officer and the Cargo Engineer should be a formal procedure to

avoid any ambiguity over who is in operational control and is to be recorded in the Deck

Operations Log.

The Officer of the watch is to be on duty at all times.

Two seamen are also on cargo duty and their duties should be fully explained to them. They

should immediately report any of the following:

- Cargo vapour or liquid leakage.

- Fire.

- Unusual phenomena.

- Mooring deficiencies.

- Indications of overside pollution or any potential source of pollution on deck.

To conform to the requirements of the ISPS Code, a third seaman is to be on security / gangway

duty at all times. All visitors to the vessel are logged on and off the vessel. This includes terminal

representatives.

Seamen should be trained to operate cargo safety trips in given circumstances. It is also strongly

recommended that seamen are given basic instruction in the local operation of loading & discharge

valves should it be necessary to adjust these valves, when the duty OOW is temporarily

unavailable for this task due to other duties.

All outside areas of the vessel are to be regularly patrolled, including accommodation decks, bridge

deck, upper deck and trunk deck. Refer also to Company, Industry publications and terminal

regulations.

For safety reasons a minimum of 2 P.O. and 6 sailors should remain onboard at all times during

discharge.

All scuppers should normally remain closed while the vessel is alongside the terminal. It is

permissible to open scuppers to drain excess water that accumulates due to heavy rain or spray

water. Prior to opening a scupper the water to be drained should be confirmed as pollutant free

and the terminal should be informed. Usually a terminal representative will board the vessel to

witness the draining. Scuppers must be closed as soon as the draining of surface water is

completed, and must never be left unattended when in the open position.

Oil absorbent pads should be placed close to the scupper to collect any oily substances which may

be carried by the out-flowing water.

Where necessary careful adjustment of the moorings, and fire wires where they are rigged as per

terminal requirements, must be made throughout the discharge operation to ensure the vessel

does not move position.

The terminal operator must always be advised before any moorings are

adjusted. Generally the terminal will monitor mooring line tensions and will advise when any

mooring requires adjustment. Prior to adjustment consideration should be given to the prevailing

current and wind directions. Two watch keepers must be available, and wires should never be

slackened on the brake, the clutch must always be engaged, and winches turned in gear. After

wires are adjusted and brakes re-applied the clutch must be disengaged. If necessary additional

man power should be used to adjust moorings to ensure that the cargo area is continuously

monitored throughout.

In port watch handover procedures

Cargo watch handovers must be comprehensive and in accordance with the Chief Officer's

standing orders. The Officer of the Watch (OOW) must complete any critical operation and

handover to his relief should be postponed until completion of any such operation.

The relieving

officer should, prior to taking over the watch, check the cargo plan and the Chief Officer's written

instructions for accuracy, sign where not already done so and, by doing so, accept the instructions

given and the responsibility for the operations carried out during the forthcoming watch period.

The Officer of the Watch must ensure that he has sufficient personnel, capable of performing their

duties, available to meet the operational requirements of his watch.

Below is more guideline for safe cargo operation on board gas carriers

Procedure for cargo planning in Liquefied Gas Carriers

Procedure for safe Cargo handling in Liquefied Gas Carriers

Details of various cargo handling equipment onboard

Cargo piping layout for LNG carriers

Procedure for commissioning the cargo system

Preparation for Cargo Transfer

Procedure for discussion prior cargo transfer

Procedure for loading Liquefied Gas Cargoes

Procedure for Cargo Conditioning in Liquefied Gas Carriers

Cargo Transfer between Vessels (STS Operation)

Procedure for segregation of Liquefied Gas Cargoes

Procedure for Stripping Liquefied Gas Cargoes

Procedure for Changing Liquefied Gas Cargoes

Displacing with Vapour of the Next Cargo (Purging)

Procedure for Water washing after Ammonia Cargoes

Details of various cargo handling equipment onboard

Gas carrier cargo containment procedure

Cargo conditioning, reliquefaction and boil-off control requirement for a liquefied gas carrier

Cargo Containment Systems in Liquefied Gas Carriers

cargo emergency shutdown requirement

damage stability guideline for liquefied gas carriers

Various Cargo handling equipments onboard

Cargo hoses connection guideline

Documents accompanying a liquid gas cargo

How LNG transferred from shore to ships cargo tanks ?

Cargo operation guideline onboard a liquefied gas carrier

Cargo piping Systems in Liquefied Gas Carriers

cargo planning requirement

cargo and pumproom safety precautions

cargo stripping guideline

Emergency response for cargo system leaks

Emergency response for cargo tank rupture

Risk of overfilling of cargo tank during loading onboard a liquefied gas carrier

Preparation for cargo transfer

cargo transfer between vessels- safety guideline

Liquefied gas cargo vapour characteristicsLiquefied gas cargo - low temperature effects

Liquefied gas carrier -monitoring cargo pressure

Cargo conditioning, reliquefaction and boil-off control requirement for a liquefied gas carrier

Cargo Containment Systems in Liquefied Gas Carriers

cargo emergency shutdown requirement

damage stability guideline for liquefied gas carriers

Various Cargo handling equipments onboard

Cargo hoses connection guideline

Documents accompanying a liquid gas cargo

How LNG transferred from shore to ships cargo tanks ?

Cargo operation guideline onboard a liquefied gas carrier

Cargo piping Systems in Liquefied Gas Carriers

cargo planning requirement

cargo and pumproom safety precautions

cargo stripping guideline

Emergency response for cargo system leaks

Emergency response for cargo tank rupture

Risk of overfilling of cargo tank during loading onboard a liquefied gas carrier

Preparation for cargo transfer

cargo transfer between vessels- safety guideline

Gas analyzing equipment Custody Transfer Measurement (CTM) System

Use of cargo as fuel -Cargo conditioning, reliquefaction and boil-off control for LNG carriers

Gas carrier cargo handling additional guidelines

- Procedures for various cargo handling equipment onboard

- Personal protective equipments for people working onboard gas carriers

- Volatile nature of liquefied gases

- How to achieve maximum drainage of liquid during discharge

- The hazards of liquefied gases - Cargo information and safety factors

More Info pages

Procedure for cargo planning in Liquefied Gas Carriers

Details of various cargo handling equipment onboard

Cargo piping layout for LNG carriers

Procedure for commissioning the cargo system

Preparation for Cargo Transfer

Procedure for discussion prior cargo transfer

Procedure for loading Liquefied Gas Cargoes

Procedure for Cargo Conditioning in Liquefied Gas Carriers

Cargo Transfer between Vessels (STS Operation)

Procedure for segregation of Liquefied Gas Cargoes

Procedure for Stripping Liquefied Gas Cargoes

Procedure for Changing Liquefied Gas Cargoes

Displacing with Vapour of the Next Cargo (Purging)

Procedure for Water washing after Ammonia Cargoes

//

Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///

Fire precautions

///

Health hazards

///

Safety Precautions

///

Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information

as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org .

Any suggestions, please Contact us !

///Links &Resources //

Terms of use///

Privacy policy///Home page///