Home page|||

LNG handling |||

LPG handling||| Other Gas products|||

Fire & Safety|||

Emergency response |||

Gas analyzing equipment on board liquefied gas carriers

An instrument which alerts someone to the presence of gas, especially in spaces where gas is not

normally expected. Gas analyzing equipment include oxygen monitors, detectors for

combustible gases, compressed breathing air monitors, and systems for detection of an array of toxic gases. Available

equipment ranges from single-gas and four-gas portables to multi-channel stationary gas detection systems.

Vapour detection equipment is required by IMO codes for a number of reasons.

- Cargo vapour in air, inert gas or the vapour of another cargo.

- Concentrations of gas in or near the flammable range.

- Concentrations of oxygen in inert gas, cargo vapour or enclosed spaces.

OXYGEN ANALYSER/INDICATORS

An instrument used to measure oxygen concentrations, expressed as a percentage by volume.

Peroxide A compound formed by the chemical combination of cargo liquid or vapour with atmospheric oxygen,

or oxygen from another source. These compounds may in some cases be highly reactive or unstable and constitute

a potential hazard.

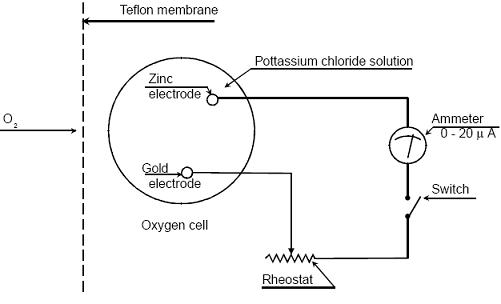

A typical indicator draws the sample through a teflon membrane into a potassium chloride solution and

activates a chemical cell. When the switch is closed current flows round the circuit and deflects the

ammeter needle. The more oxygen absorbed by the solution the greater the current and needle

deflection indicating the percentage oxygen in the sample.

COMBUSTIBLE GAS INDICATORS

portable multi gas detection systems monitor a variety of different gases including, Carbon monoxide (CO), Hydrogen sulfide (H2S), Oxygen (O2), Carbon dioxide (CO2) and Combustible gases. We offer monitors for other toxic gases such as Ammonia (NH3), Chlorine (Cl2), Sulfur dioxide (SO2), Nitric oxide (NO), Nitrogen dioxide (NO2), etc

The basic electric circuit (Wheatstone Bridge) of the combustible gas indicator is shown. Sample gas to

be measured is aspirated over the specially treated sensor filament which is heated by the bridge

current. Although the gas sample may be below the lower flammable limit, it will burn catalytically on

the filament surface. In so doing it will raise the temperature of the filament and thereby increase its

electrical resistance and so unbalance the bridge. The resultant imbalance current is shown on the

meter and is related to the hydrocarbon content of the sample gas.

TOXICITY DETECTORS

Toxic gas detectors commonly operate on the principle of absorption of the toxic gas in a chemical tube

which results in a colour change. A common type of toxic gas detector is illustrated. Immediately prior

to use the ends are broken from a sealed glass tube. This is inserted into the bellows unit, and a

sample aspirated through it. The reaction between the gases being sampled and the chemicals

contained in the tube causes a colour change.

Usually readings are taken from the length of the colour

stain against scale indicators marked on the tube and are expressed as parts per million (ppm). Some

tubes, however, require the colour change to be matched against a control provided in the instructions.

As tubes may have a specific shelf life they are date stamped and also accompanied by an instruction

leaflet which lists any different gases which being present may interfere with the accuracy of the

indication.

It is important to aspirate the bulb correctly if reliable results are to be obtained. Normally, the bellows

are compressed and the unbroken tube inserted. The instrument is then checked for leaks prior to

breaking the tube; if found to be faulty it must be replaced at once.

Maintenance requirement of gas analyzing equipment

(1) The portable gas and oxygen analyzers should be appropriate to the cargoes being carried and are they in good order.

(2) Each vessel should carry at least two each oxygen, % volume hydrocarbon, LEL and toxic gas analyzers.

(3) Personal oxygen and hydrocarbon analyzers, which can be carried in a pocket or on a belt, should be available for tank, enclosed space or pump room entry.

(4) Officers should be familiar with use and calibration of portable oxygen and hydrocarbon analyzers.

(5) A procedure must require that all oxygen and hydrocarbon analyzers are checked for correct operation before each use. Nitrogen must generally be used when calibrating oxygen analyzers, but some multiple function analyzers use a test gas which serves all the functions of the analyzer with one sample gas and which has an oxygen content of 20.9%.

(6) Officers should take a record of regular testing and calibration of portable analyzers.

(7) The manufacturers’ recommended intervals for servicing the equipment ashore must be being adhered to and there must be a routine for the replacement of parts on board, such as filters, at the intervals recommended by the manufacturers. Sufficient span calibration gas should be available for the types of fixed and portable analyzers on board.

(8) It should be noted that the use of a self test facility does not necessarily mean that an analyzer is operating correctly. It is possible for various reasons for a machine to satisfactorily self-test, but then fail to register a lack of oxygen or the presence of gas. The only way to be sure that a machine is operating satisfactorily is to use a sample check gas.

Related Information:

Custody Transfer Measurement (CTM) System

Records of the calibration of key cargo instrumentation, including temperature and pressure gauges

The high level alarm system

Manifold arrangements

Safety equipment

Decontamination showers and an eye-wash

Cargo tank ruptures due to increased pressure - emergency procedure for gas carriers

Loss of power supplies - emergency actions

Risk and hazards of Equipment failure

Loss of Instrumentation during Unloading Operations - Recommended actions by Liquefied Gas carriers

Risk and hazards of Nitrogen Loss

Gas carriers Loss of Instrumentation during Loading Operations

Gas carriers Structural Damage due to Incorrect Loading/Unloading Sequence

Encountering High Winds and/or Waves - countermeasures

Safety guideline for changing previous cargo

// Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///Fire precautions

///Health hazards

///Safety Precautions

///Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information

as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org .

Any suggestions, please Contact us !

///Links &Resources //

Terms of use///

Privacy policy///Home page///