Home page|||

LNG handling |||

LPG handling||| Other Gas products|||

Fire & Safety|||

Emergency response |||

Gas carrier guide - The principle products - Properties and hazards of various liquefied gases

Most liquefied gases are hydrocarbons and the key property that makes hydrocarbons the world’s primary energy source – combustibility – also makes them inherently hazardous. Because these gases are handled in large quantities, it is imperative that all practical steps are taken to minimize leakage and to limit all sources of ignition.

The Principal Products described are as below :-

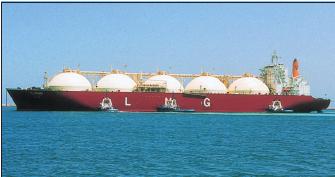

Liquefied Natural Gas (LNG)

Natural gas is transported either by pipeline as a gas or by sea in its liquefied form as LNG. Its composition varies according to where it is found but methane is by far the predominant constituent, ranging from 70% to 99%. Natural gas Density - 26.5 LB./Cu Ft. Boiling point - (-259 degree F ). They are lighter than air (Gas Density - 0.47) & (Air - 1.0). So natural gas rises under normal atmospheric conditions.

Fig: Spherical or moss type lng carrier

LNG comes from natural gas that's been cooled to

below -256 degrees F, with some impurities removed.

Natural gas comes from underground gas fields by

itself or in oil fields, along with crude oil. There's very

little difference between natural gas and vaporized

LNG; mostly LNG is a little purer; before liquefying

the natural gas engineers remove the pollutants, like

sulfur.

LNG, as mentioned, is very cold natural gas that is in

a liquid form rather than gas. Chemically, it's mostly

methane, with small amounts of ethane, propane,

and butane. LPG (liquefied petroleum gas), some

times referred to as bottled gas, is a heavier gas that

can be liquefied under pressure or by refrigeration. It

is mostly propane and butane. Gasoline is heavier

still and is a liquid at room temperature. Heating oil

is even heavier and doesn't boil unless heated. And

asphalt is so heavy that it's a solid. But in a way they

are all pretty similar, because they all burn.

Natural Gas Liquids (NGLs)

Associated gas, found in combination with crude oil, comprises mainly methane and NGLs. The NGLs are made up of ethane, LPGs and gasoline. A small number of terminals, including several facilities in Europe, have the ability to strip methane from the gas steam and to load raw NGLs onto semi-pressurized gas carriers. These ships are modified with additional compressor capacity for shipment to customers able to accept such ethane-rich cargoes. These NGLs are carried at -80 degrees at atmospheric pressure or at -45 degree at a vapour pressure of 5 bar.

The Liquefied Petroleum Gases (LPG)

The liquefied petroleum gases comprise propane, butane and mixtures of the two. Butane stored in cylinders and thus known as bottled gas, has widespread use as a fuel for heating and cooking in remote locations. However, it is also an important octane enhancer for motor gasoline and a key petrochemical feedstock. Propane, too, is utilized as a bottled gas, especially in cold climates (to which its vapour pressure is more suited). However, LPG is mainly used in power generation, for industrial purposes such metal cutting and as a petrochemical feedstock.

Ammonia

With increased pressure on the world’s food resources, the demand for nitrogen-containing fertilizers, based on ammonia, expanded strongly during the 1970s and 1980s. Large-scale ammonia plants continue to be built in locations rich in natural gas which is the raw material most commonly used to make this product. Ammonia is also used as an on-shore industrial refrigerant, in the production of explosives and for numerous industrial chemicals such as urea.

Ethylene

Ethylene is one of the primary petrochemical building blocks. It is used in the manufacture of polyethylene plastics, ethyl alcohol, polyvinyl chloride (PVC), antifreeze, polystyrene and polyester fibers. It is obtained by cracking either naphtha, ethane or LPG.

Propylene

Propylene is a petrochemical intermediate used to make polypropylene and polyurethane plastics, acrylic fibers and industrial solvents.

Butadiene

Butadiene is a highly reactive petrochemical intermediate. It is used to produce styrene, acrylonitrile and polybutadiene synthetic rubbers. Butadiene is also used in paints and binders for non-woven fabrics and, as an intermediate, in plastic and nylon production. Most butadiene output stems from the cracking of naphtha to produce ethylene.

Vinyl Chloride

Vinyl chloride is an easily liquefiable, chlorinated gas used in the manufacture of PVC, the second most important thermoplastic in the world in terms of output. Vinyl chloride not only has a relatively high boiling point, at -14 degrees, but is also, with a specific gravity of 0.97, much denser than the other common gas carrier cargoes.

Related Information:

- Design characteristics of liquefied gas carriers

How liquefied gas carriers are built ?

Gas carriers are high-tech ships, designed with safety and security in mind & using special materials and designs to safely handle the very cold LNG. They are robustly designed and constructed and the majority of hazards are minimised by strict compliance with the requirements of the International Maritime Organization (IMO) and other organisations during the design process. ....

- Liquefied gas carrier -applicable regulations

The Master, Chief Officer, Chief Engineer, and personnel engaged in liquefied gas handling shall comply with the following rules and regulations :

(1) The Gas Carrier Codes

.....

- Liquefied gases - Flammability

All liquefied gases presently transported in bulk by sea, with the exception of chlorine and nitrogen, are flammable. The vapours of liquefied gases are generally as easily ignited as those of oil cargoes. ....

- Dispersal of Vented Cargo Vapours

Behaviour of LNG in the cargo tanks - Dispersal of vented cargo vapours

When loaded in the cargo tanks, the pressure of the vapour phase is maintained substantially constant, slightly above atmospheric pressure....

- Hazards with carrying propylene oxide mixtures

Propylene oxide (PO) is an eserine with wide flammable limits of 2.8 - 37% by volume. The TLV of this product is 100 ppm whilst its odour threshold is 10 ppm. Exposure to the liquid or high concentrations of the vapour can lead to eye burns, skin irritation and blistering, vomiting, lack of co-ordination and depression

.....

-

Safety equipment

- Liquefied gas cargo reactivity

-

Liquefied gas cargo corrosion

- Liquefied gas cargo vapour characteristics

- Liquefied gas cargo - low temperature effects

External links :

-

International maritime organization

// Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///Fire precautions

///Health hazards

///Safety Precautions

///Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information

as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org .

Any suggestions, please Contact us !

///Links &Resources //

Terms of use///

Privacy policy///Home page///