Home page|||

LNG handling |||

LPG handling||| Other Gas products|||

Fire & Safety|||

Emergency response |||

Low Temperature Effects in gas carrier - Causes of Brittle Fracture

What is Brittle Fracture ?:

Most metals and alloys become stronger but less ductile at low temperatures (i.e. the tensile and yield strengths increase but the material becomes brittle and the impact resistance decreases) because the reduction in temperature changes the material’s crystal structure.

Normal shipbuilding steels rapidly lose their ductility and impact-strength below 0 degree. For this reason, care should be taken to prevent cold cargo from coming into contact with such steels, as the resultant rapid cooling would make the metal brittle and would cause stress due to contraction. In this condition the metal would be liable to crack. The phenomenon occurs suddenly and is called “brittle fracture”.

However, the ductility and impact resistance of materials such as aluminum, austenitic and special alloy steels and nickel improve at low temperatures and these metals are used where direct contact with cargoes at temperatures below -55 degree is involved.

Contact with LNG chilled to its temperatures of about –160 degree C will damage living tissue.

Most metals lose their ductility at these temperatures; LNG may cause the brittle fracture of many

materials. In case of LNG spillage on the ship’s deck, the high thermal stresses generated can

result in the fracture of the steel.

Avoidance of cold shock to metal

Structural steels can suffer brittle fracture at low temperatures. Such failures can be catastrophic

because, once the steel has become brittle, little energy is required to propagate a fracture once it

has been initiated.

Plain carbon structural steels have a ductile to brittle behaviour transition which occurs generally in

the range +30 degree C to –50 degree C. This precludes their uses as LNG material (carriage temperature –

162 degree C).

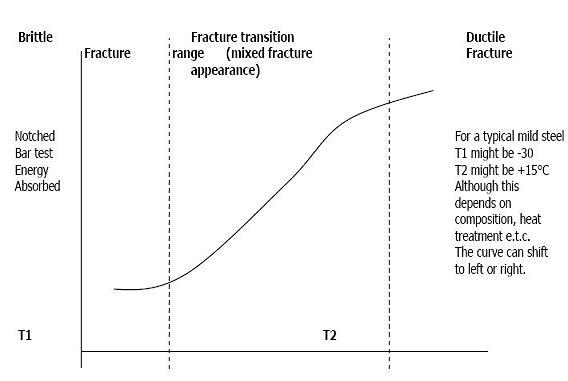

The ductile to brittle transition is usually monitored by measuring the energy absorbed in breaking

a notched bar and the transition curve, as shown in illustration “Structural Steel Ductile to Brittle

Transition Curve”, is typical for plain carbon steels.

For this reason, materials which do not show such sharp transition from ductile to brittle fractures

as the temperature is lowered, have found obvious application for use in cryogenic situations such

as liquid Methane carriers. Examples are Invar (36% nickel-iron alloy), austenitic stainless steel,

9% nickel steel and some aluminium alloys such as 5083 alloy.

All of these materials behave in a ductile manner at –162 degree C, so that the chance of an unstable

brittle fracture propagating, even if the materials were overloaded, is negligible.

Fig: STRUCTURAL STEEL DUCTILE TO BRITTLE TRANSITION CURVE

In order to avoid brittle fracture occurring, measures must be taken to ensure that LNG and liquid

Nitrogen do not come into contact with the steel structure of the vessel. In addition, specialist

equipment is provided to deal with any leakages, which may occur.

The manifold areas are equipped with a stainless steel drip tray, which collects any spillages and

drains it overboard. The ship, in way of the manifolds, is provided with a water curtain, which is

supplied by the deck fire main. The fire main must always be pressurized and the manifold water

curtain in operation when undertaking any cargo operations. Additionally, fire hoses must be laid

out to each liquid dome to deal with any small leakages, which may develop, at valves and flanges.

Permanent drip trays are fitted underneath the items most likely to cause problems and portable

drip trays are provided for any other needs.

During any type of cargo transfer, and particularly whilst loading and discharging, a constant patrol

must be conducted on deck to ensure that no leakages have developed.

In the event of a spillage or leakage, water spray should be directed at the spillage to disperse and

evaporate the liquid and to protect the steelwork. The leak must be stopped, suspending cargo

operations if necessary.

In the event of a major leak or spill, the cargo operations must be stopped immediately, the

general alarm sounded and the emergency deck water spray system put into operation.

Related Information:

- Low Cargo Temperature Effects -Ice Formation in gas carrier cargo system

- How to cool down cargo system - a brief guide to Liquefied gas carrier

- Preventive measures against spillage of low temperature cargo in Liquefied gas carrier

- Low Cargo Temperature Effects -What is rollover of Liquefied gas cargo ?

Other info pages:

Preparatory operations for drydocking

Hazards of electrical equipment on board

Discussion prior to cargo transfer in liquefied gas carrier

Handling LPG And ammonia cargo - preparation for loading

The risk of discharging cargo - a brief outline to liquefied gas carriers

The risk of laden voyage - a brief guide to liquefied gas carriers

Connection and disconnection of cargo hoses and hard arms

Cargo conditioning, reliquefaction and boil-off control requirement for a liquefied gas carrier

Cargo Containment Systems in Liquefied Gas Carriers

cargo emergency shutdown requirement

damage stability guideline for liquefied gas carriers

Various Cargo handling equipments onboard

Cargo hoses connection guideline

Documents accompanying a liquid gas cargo

How LNG transferred from shore to ships cargo tanks ?

Cargo operation guideline onboard a liquefied gas carrier

Cargo piping Systems in Liquefied Gas Carriers

cargo planning requirement

cargo and pumproom safety precautions

cargo stripping guideline

Emergency response for cargo system leaks

Emergency response for cargo tank rupture

Risk of overfilling of cargo tank during loading onboard a liquefied gas carrier

Preparation for cargo transfer

cargo transfer between vessels- safety guideline

// Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///Fire precautions

///Health hazards

///Safety Precautions

///Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org . Any suggestions, please Contact us !

//Links &Resources //

Terms of use//

Privacy policy //Home page