Home page|||

LNG handling |||

LPG handling||| Other Gas products|||

Fire & Safety|||

Emergency response |||

Drydocking preparation for a liquefied gas carrier

Preparatory operations for drydocking start with the disposal of all remaining liquid and ends with the creation of the tank atmosphere meeting all criteria a dockyard requires. On a voyage just prior to dry-docking, cargo should be discharged as much as possible to leave less residual cargo on board, and such liquid left over should be disposed of by gasification.

The remaining liquid is gasified by injection into the liquid from the tank bottom hot gas which was drawn with compressors in operation. The generated gas is sent to the shore when the vessel is alongside a berth, and released into the atmosphere when at sea.

The detail preparation of drydocking may be carried out in the following sequence.

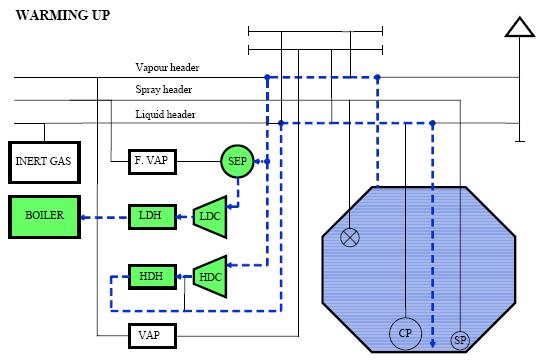

Warming Up

Tank warm up is part of the gas freeing operations carried out prior to dry-docking or when

preparing tanks for inspection purposes.

The tanks are warmed by circulating heated LNG vapour. The vapour is re-circulated using the HD

compressors and heated using the vapour heater.

Initially the hot vapour is introduced through the filling lines to the bottom of the cargo tank to

facilitate the evaporation of any liquid remaining in the tank. In a second step, when the

temperatures have a tendency to stabilize, hot vapour is introduced through the top of the tank via

the vapour line.

When at sea, excess vapour generated during the warm up operation is vented to atmosphere or

burned in the boilers. When alongside, it may be returned to shore.

Initially the tank temperatures will rise slowly as evaporation of the LNG proceeds, accompanied by

high vapour generation and venting. On completion of evaporation, tank temperatures will rise

rapidly and the rate of venting will fall.

The warming should continue until the vapour temperature within the tank is between +5 and

+10C.

It is important that tank temperature is above the dewpoint of the Inert Gas to be introduced.

Failure to ensure this will result in water condensing on the tank side on introduction of the Inert

Gas.

(1) On a voyage just prior to dry-docking, cargo should be discharged as much as possible to leave less residual cargo on board, and such liquid left over should be disposed of by gasification.

(2) The remaining liquid is gasified by injection into the liquid from the tank bottom hot gas which was drawn with compressors in operation. The generated gas is sent to the shore when the vessel is alongside a berth, and released into the atmosphere when at sea.

(3) During the operation its progress should be monitored by taking temperatures as well as measuring the concentration of oxygen in cargo tanks.

The criteria of temperature are as follows:

i)C3 Tank minimum -20 degree C

ii)C4 Tank minimum 5 degree C.

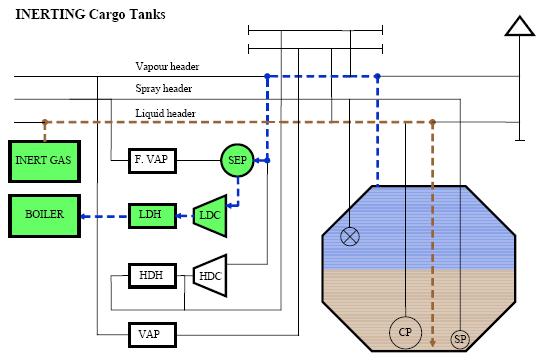

Inerting

After the tanks have been sufficiently warmed, the LNG vapour is displaced with inert gas. This

operation reduces the Methane contents in the cargo tanks before air is introduced, thus avoiding

the danger of a flammable atmosphere.

Inert gas is introduced at the bottom of the tank through the LNG filling line. Vapour from the

tanks is vented through the vapour header. This operation is continued until the hydrocarbon

contents is reduced to <1.5%

During the time that the inert gas plant is in operation for gas freeing the tanks, the inert gas

should also be used to gas free all other LNG liquid, spray cooling and vapour piping. The various

sections of piping are blown through with inert gas from the LNG liquid header, or from the tanks

after they have been gas freed.

It is normal to inert all tanks simultaneously in order to complete the overall operation minimum

time.

(1) After completing the warming-up operation, in order to get cargo tanks gas-freed for Dry-docking, flammable gases are removed by nitrogen gas or other inert gas to prevent the generation of a flammable atmosphere.

After the inerting operation of cargo tanks have completed, cargo pumps and discharge lines and other systems are inerted by making use of inert gas pressurized in cargo tanks. Bearing in mind that flammable gases are released on to the upper deck, crew members should conduct the operation by paying attention to the location of workers and sources of ignition (Cargo vapor shall be kept under 2 Vol%).

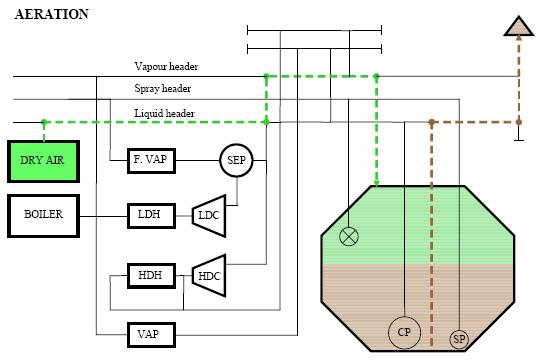

Aerating

Prior to entry into the cargo tanks the inert gas must be replaced with air.

With the inert gas system in dry air mode, the cargo tanks are purged with dry air until a reading

21% O2 by volume is reached.

The dry air is introduced to the cargo tanks via vapour header.

The inert gas/dry air mixture is exhausted from the bottom of the tank via filing line and liquid

header.

The operation is complete when all tanks have 21% Oxygen value, a Methane content of <0.2%

by volume (or whatever is required by the Local Authority) and a dewpoint below –40 C.

Before entry, test for traces of noxious gases (Carbon Dioxide <0.5% by volume and Carbon

Monoxide <50ppm) which may have been constituents of the Inert Gas. In addition, take

appropriate precaution as given in the Tanker Safety Guide and other relevant publications.

After the inerting operation, comes an operation in which air is injected into tanks until after the content of each gases reaches the following criteria so that man can enter inside tanks.

i) Flammable Gas : Less than 1 % LEL

ii) CO2 : 0.5 Vol% or less

iii)CO : 0.005 Vol% or less

iv) O2 : 21 Vol %

See more information on gas carrier operation:

Safety checklist for gas carrier

LPG & Ammonia cargo handling -Precautions on cargo operation

The risk of ballast voyage - a brief guide to liquefied gas carriers

Hazards of electrical equipment on board

Discussion prior to cargo transfer in liquefied gas carrier

Handling LPG And ammonia cargo - preparation for loading

The risk of discharging cargo - a brief outline to liquefied gas carriers

The risk of laden voyage - a brief guide to liquefied gas carriers

Connection and disconnection of cargo hoses and hard arms

Related Information:

- Inerting of Cargo Tanks prior loading LNG cargo

- Initial Cool Down of cargo tanks

Procedure for loading Liquefied Gas Cargoes

Procedure for Cargo Conditioning in Liquefied Gas Carriers

Cargo Transfer between Vessels (STS Operation)

Procedure for segregation of Liquefied Gas Cargoes

Procedure for Stripping Liquefied Gas Cargoes

Procedure for Changing Liquefied Gas Cargoes

Displacing Atmosphere with Inert Gas (Inerting)

Displacing with Vapour of the Next Cargo (Purging)

Procedure for Water washing after Ammonia Cargoes

// Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///Fire precautions

///Health hazards

///Safety Precautions

///Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information

as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org .

Any suggestions, please Contact us !

///Links &Resources //

Terms of use///

Privacy policy///Home page///