Fig:LNG carrier underway

Risk prevention and mitigation techniques are

especially useful in zones where the potential

impact on public safety and property can be high.

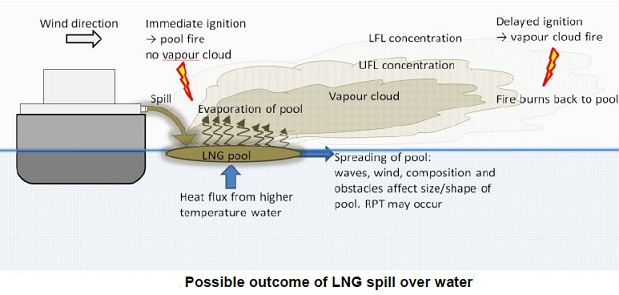

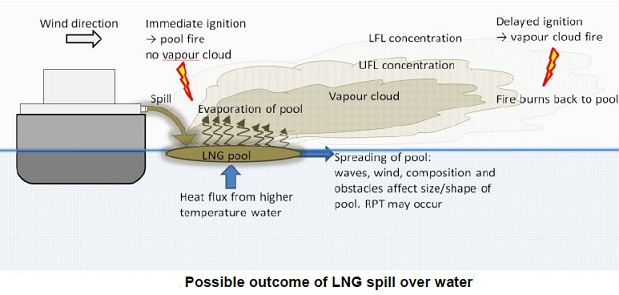

The hazards of brittle fracture, rapid phase transitions, and explosions in confined ship spaces, as well

as cascading events that may result from the extreme

fire exposure a ship would experience if a nominal

12,500 m3 spill on water around the ship was ignited,

will require careful consideration. The definition of

The majority of liquefied gases are clean, non-polluting, products and

create no danger to the marine environment. If however certain

liquefied gases spill on to the sea you should be aware that they may:

- create large quantities of vapour sea water rapidly vapourises

the liquid gas- which may cause a fire or explosion or a health

hazard.

-

generate toxic vapours, which can drift, sometimes over a

considerable distance.

- dissolve in seawater and cause local pollution

The Data Sheets will give information on pollution, if any

Pollution is most likely to occur during cargo or bunkering operations:

if the operation is not correctly monitored

if the cargo hose or loading arm connections are not properly

made

when disconnecting cargo lines that have not been drained.

if moorings are not checked and excessive strain is placed on the

cargo connections or the ship "breaks out" of the berth.

if cargo equipment is not properly maintained

Any spillage of LNG on any steelwork, unless stainless steel or wood-sheathed, will cause stresses

and it is most likely serious brittle fractures will occur.

As soon as any leak or spill of LNG is exposed to ambient temperatures, the liquid will vaporise or

‘boil-off’. This vaporisation will occur in two phases. Initially, for a period of from 20-30 seconds,

there will normally be a high rate of boiling as the heat for vaporisation is taken from the liquid

spill itself and the immediate surrounding areas. Secondly, the cold vaporised gas begins to

insulate the liquid surface and the evaporation rate will level off at a lower steady rate depending

on how quickly heat can be transferred to the LNG from the surrounding area. This vaporisation

rate may be increased by:

- Continuing leakage, i.e. greater volume exposed to atmosphere.

- Wind.

- Application of water.

- Ignition, i.e. greater heat flow to the liquid.

- Agitation of the surface.

Thus, spraying an un-ignited spillage of LNG with water will speed up the vaporisation and reduce

the hazards of cold fractures, fire or ignition. Alternatively, spraying with water on to LNG which

has been ignited will increase the vaporisation rate and hence the burning rate. The use of solid

water jets on LNG spills may cause splashing, leading to cold fractures or frost burns or, if ignited,

may seriously aggravate the fire.

Immediately after vaporisation, natural gas is 1·4 times heavier than air. As the gas warms, its

density will decrease, becoming the same as air at approximately –120°C and reaching the value of

0·55 at 15oC. There may, therefore, be a tendency for cold vapours to form a layer around the

spill in a similar manner to other hydrocarbon gases. Fortunately, this layering will normally be

visible due to the condensation of atmospheric moisture.

However, unlike other hydrocarbon

gases, natural gas quickly becomes buoyant and, except in enclosed spaces, will rise and disperse

rapidly as it warms. This dispersion is further aided by the very rapid diffusion properties of

methane in air. Where spills may have entered enclosed spaces, it is important to recognise that

gas pockets may become trapped near deckhead structures, etc.

In the case of a leakage or spillage of LNG, the following general procedure should be followed:

- Isolate source of LNG. If loading/discharging, the ESD system should be activated.

- Summon assistance.

- Protect the hull from risk of cold fracture.

- Speed vaporisation to minimise ignition risk.

The exact procedure will depend upon the nature of the incident, inclusive of size of spill, location,

ambient conditions and ignition risks.

Where LNG spills onto water, Rapid Phase Transition may occur causing loud bangs similar to ones

that may be heard during an explosion. However, there are no flames or explosion when this

occurs.

Related Information:

-

Preventive measures against liquefied gas spillage

- Liquefied gas carrier safety training

- Leaks on the Cargo System, Continuous Flow - how to prevent

- Personal protective equipments for people working onboard gas carriers

- LNG tank leaks and immediate action by gas carriers

- Minor or major leaks from LNG tanks

- Initial Cool Down of cargo tanks

- Leaks from a Loading Arm due to Tidal or Current Effects

Defining various gas carrier types

Fuel flexibility of LNG ships

Procedures for LNG cargo loading

Liquefied gases - Properties And Hazards

Safety guideline for changing previous cargo

Reactivity of liquefied gas cargo

Initial Cool Down of cargo tanks

Procedures for LNG cargo loading

Procedures for LNG cargo discharging

External links :

-

LNG industry online training company

//

Home page///

LNG handling ///

LPG handling///

Sea transport ///

Gas products///

Cargo work

///

Fire precautions

///

Health hazards

///

Safety Precautions

///

Emergency response ///

Copyright © Liquefied Gas Carrie.com All rights reserved.

The content published in this website are for general reference only. We have endeavoured to make the information

as accurate as possible but cannot take responsibility for any errors. For latest information please visit www.imo.org .

Any suggestions, please Contact us !

///Links &Resources //

Terms of use///

Privacy policy///Home page///